1. Structural characteristics of bipolar stepper motors

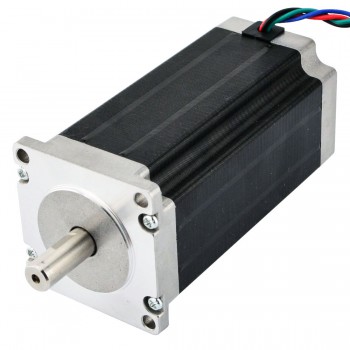

A bipolar stepper motor is a type of motor that converts electrical pulse signals into precise angular or linear displacements. The structural characteristics of a bipolar stepper motor are one winding per phase, no center tap, and usually four wires, corresponding to the two ends of each winding. The rotor consists of permanent magnets, while the stator has multiple electromagnets. The rotor can be rotated step by step by switching the direction of the current in each winding in a specific order.

2. Working principle of bipolar stepper motors

The working principle of a bipolar stepper motor is to generate a change in the magnetic field by changing the direction of the current, thereby driving the rotor to rotate. When current passes through the coil, a magnetic field is generated that attracts or repels the magnetic poles on the rotor, thereby driving the rotor to rotate. The direction and speed of the motor's rotation can be controlled by precisely controlling the sequence and frequency of the current pulses applied to each coil.

3. Driving characteristics of bipolar stepper motors

1. High-precision positioning: Bipolar stepper motors use stepping technology, and each step position is very accurate, which can accurately locate the required position. This high-precision positioning feature makes bipolar stepper motors have obvious advantages in occasions where precise position control is required.

2. Strong reversibility: Bipolar stepper motors have two independent coils, and the direction of the current in the coils can be changed to achieve forward and reverse rotation of the motor. This strong reversibility makes bipolar stepper motors very adaptable in occasions where the direction of the motor needs to be changed frequently.

3. Large static torque: In a stationary state, bipolar stepper motors can provide very high torque output, which allows them to withstand various loads and provide good starting power when they start to rotate. This large static torque feature makes bipolar stepper motors have good application prospects in occasions where they need to withstand large loads.

4. Sensitive dynamic response: Bipolar stepper motors have a fast dynamic response speed and can quickly adjust the control amount to cope with system changes. This makes bipolar stepper motors very useful in situations where fast response is required.

5. High control accuracy: The speed and angle of bipolar stepper motors can be precisely adjusted according to the size and frequency of the control signal. This high control accuracy makes bipolar stepper motors very useful in situations where high-precision control is required.

6. Complex drive circuit: Compared with unipolar stepper motors, bipolar stepper motors require more complex drive circuits to provide forward and reverse currents. This increases the complexity and cost of the circuit, but also provides higher control accuracy and flexibility.

4. Selection steps for bipolar stepper motors

1. Clarify application requirements: First, you need to determine parameters such as load requirements, rotation speed, and position accuracy. Understand the load characteristics of the equipment or mechanism that the motor needs to drive, including the size of the load, moment of inertia, friction coefficient, etc.

2. Select the motor type: Select the appropriate motor type according to the load requirements and rotation speed. Bipolar stepper motors are generally suitable for applications that require higher output torque and stable performance.

3. Determine the step angle: The step angle refers to the angle that each stepper motor rotor rotates. The step angle of a bipolar stepper motor is usually 1.8 degrees or 0.9 degrees. The choice of step angle depends on the load accuracy requirements. The smaller the step angle, the higher the resolution of the rotor rotation, but it requires a more complex circuit drive.

4. Select the torque: Select the appropriate motor model according to the required torque size (that is, the torque size of the object to be driven). Generally speaking, if the torque is below 0.8Nm, you can choose motors of specifications such as 20, 28, 35, 39, and 42; if the torque is around 1Nm, it is more appropriate to choose a 57 motor; if the torque is several Nm or more, you need to choose a stepper motor of specifications such as 86, 110, and 130.

5. Consider the relationship between speed and torque: The output torque of the stepper motor is inversely proportional to the speed. At low speed, the output torque is large; at high speed, the torque is small.

6. Select no-load starting frequency: No-load starting frequency is an important indicator for selecting motors. If you need to start and stop frequently in an instant and the speed is high, you usually need to choose a motor with a higher no-load starting frequency.

7. Consider the use environment and special needs: Choose the appropriate motor type according to the use environment, such as waterproof and oil-proof motors are suitable for some special occasions.

Source:https://blogg.alltforforaldrar.se/randolph/2025/03/24/bipolar-stepper-motor-driving-characteristics-and-selection-steps/

Posted

Mar 24 2025, 02:27 AM

by

Randy45