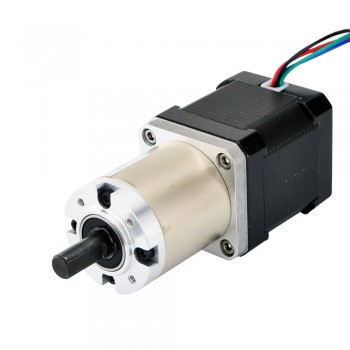

1.Brief introduction to geared stepper motors

Geared stepper motors are a device that combines stepper motors and gear mechanisms, and are mainly used to increase the output torque and reduce the speed of stepper motors. The stepper motor itself is a motor that converts electrical pulse signals into angular displacement or linear displacement. Each time an electrical pulse signal is received, the motor rotor will rotate a fixed angle or move forward.

2.Working principle of geared stepper motors

The working principle of geared stepper motors is based on the basic working principle of stepper motors. The stepper motor receives an electrical pulse signal, and each pulse causes the rotor to rotate a fixed angle. When the stepper motor is combined with a gear mechanism, the gear mechanism can amplify the torque output of the motor, so that the motor can provide greater power at low speeds, while reducing the speed and increasing the output torque.

3.Main features of geared stepper motors

1.Accurate positioning capability: Geared stepper motors can provide higher output torque and more precise position control through a gear transmission system. The gear ratio can amplify the output torque of the motor, so that the motor can still provide a large torque at low speeds, which is suitable for application scenarios that require high-precision positioning.

2.High torque output: Due to the transmission effect of gears, geared stepper motors can provide higher torque output at low speeds, which is very beneficial for applications that require high torque. In addition, gear transmission can also reduce the vibration and noise of the motor and improve the stability of the system.

3.Easy to control: Stepper motors are controlled by electrical pulse signals, which are easy to implement open-loop control and do not require a complex feedback system. This makes stepper motors widely used in systems that require simple control, such as CNC machine tools.

4.No cumulative error: The output angle of the stepper motor is strictly proportional to the number of input pulses, and there is no cumulative error. This makes the stepper motor perform well in systems that require high-precision position control.

5.Applicable scenarios: Due to these characteristics of stepper motors, they are widely used in CNC machine tools, automation equipment, robots, printers, and other fields that require precise control and positioning.

4.Selection principles of geared stepper motors

1.Load capacity: The selection of geared stepper motors must first consider their load capacity, including factors such as load size, inertia, and acceleration. If the load is too large, a stepper motor with greater torque output needs to be selected, usually by increasing the number of stator electromagnetic windings.

2.Accuracy requirements: Accuracy is one of the important considerations for selecting a geared stepper motor. The step angle and nominal resolution of the stepper motor directly affect the accuracy of the rotation. Smaller step angles correspond to higher accuracy requirements.

3.Power supply and controller: The quality of the power supply and controller has a significant impact on the reliability and stability of the stepper motor. An unstable power supply or a controller that cannot be accurately controlled may cause the rotation to stall or lose reliability.

4.Step angle: The step angle is the angle that the stepper motor rotates each time it receives an electrical pulse signal. The choice of step angle depends on the load accuracy requirements. For high-precision positioning, a motor with a smaller step angle should be selected.

5.Static torque: Static torque refers to the maximum torque that a stepper motor can generate when it is stationary. When selecting static torque, the type of load the motor is working on needs to be considered, including inertial load and friction load. Generally, the static torque should be 2-3 times the friction load to ensure that the motor has sufficient torque reserve during startup and operation.

6.Current: Motors with the same static torque will have very different operating characteristics due to different current parameters. To select a suitable current value, you need to refer to the torque-frequency characteristic curve of the motor, and try to choose a smaller current value to reduce heat generation and energy consumption while meeting the torque requirements.

7.Relationship between speed and torque: The output torque of the stepper motor will gradually decrease with the increase of speed. When selecting, you should refer to the torque-frequency characteristic curve of the motor based on the maximum speed and required torque of the load, and select a motor that can provide sufficient torque within the working speed range.

8.Subdivision drive: Try to choose a subdivision drive and make the drive work in a subdivision state to improve the control accuracy and running stability of the motor.

Posted

Jan 03 2025, 12:58 AM

by

Randy45