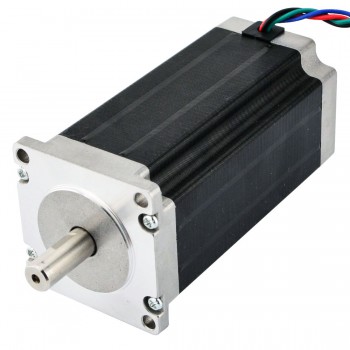

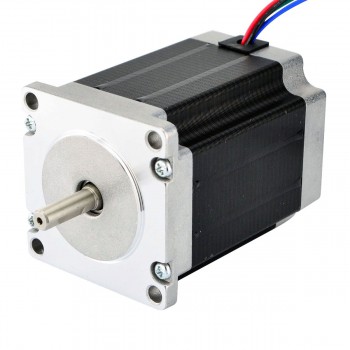

1.Definition of bipolar stepper motors

The bipolar stepper motor, also known as a two-phase stepper motor, has a structural feature that it contains two independent coils inside the motor, each coil has two wires, a total of four wires, which are used to control the operation of the motor. This design allows the motor to be reversed by changing the direction of the current in the coil during operation without changing the motor structure.

2.Structural characteristics of bipolar stepper motors

1.Coils and leads: Bipolar stepper motors usually contain two main coils (or phases), each coil has two wires, a total of four wires, which are used to control the rotation of the motor. This design allows the motor to be reversed by changing the direction of the current in the coil during operation, thereby achieving motor reversal without changing the motor structure.

2.Stator and rotor: The stator usually contains 8 teeth, each of which is wound with a two-phase bipolar winding to achieve precise control of the motor. The rotor consists of permanent magnets with north and south poles, and the stator has four electromagnets (A, B, C, D) arranged in pairs, each pair forming one phase of the motor. When current flows through one of the windings, a magnetic field is generated that attracts or repels the rotor poles, depending on the polarity of the current. By switching the direction of the current in each winding in a specific order, the rotor can be rotated step by step.

3.Applications of bipolar stepper motors

1.Industrial automation: Bipolar stepper motors have important applications in industrial automation. Due to their high-precision positioning and strong reversibility, bipolar stepper motors are often used in situations where precise position control is required. For example, in printers and scanners, bipolar stepper motors can ensure the accuracy and stability of printing and scanning.

2.Medical equipment: In medical equipment, the high precision and dynamic response sensitivity of bipolar stepper motors make them an ideal choice. For example, in surgical instruments and diagnostic equipment, bipolar stepper motors can provide precise position control and fast response speed, ensuring the accuracy and reliability of the equipment.

3.Precision instruments: In the field of precision instruments, bipolar stepper motors are also widely used. Due to their high-precision positioning and large static torque, bipolar stepper motors are often used in situations that require high-precision control. For example, in microscopes and measuring instruments, bipolar stepper motors can provide stable performance and precise control.

4.Small industrial machines: In small industrial machines, bipolar stepper motors are cost-effective and easy to drive, and are suitable for open-loop systems. For example, in office equipment such as laser engraving machines, 3D printers, and laser printers, bipolar stepper motors can provide stable performance and precise control.

4.Precautions for the use of bipolar stepper motors

1.Keep clean and dry: In order to ensure the long-term normal operation of the stepper motor, the motor needs to be kept clean and dry. Before use, remove dust accumulation, ensure that the cooling conditions of the motor are good, and the temperature must not exceed the rated temperature to avoid affecting the life of the motor.

2.Avoid overload: When using a stepper motor, be sure to ensure that the motor is not greater than its rated load, otherwise it may cause the motor to overload, resulting in protection power failure, increased noise, and even motor burnout.

3.Avoid long-term continuous operation: Long-term continuous operation of the stepper motor will cause the temperature to rise, affecting stability and life. It is necessary to arrange the running time reasonably to give the motor sufficient rest time to reduce temperature and noise.

4.Temperature control: The temperature of the stepper motor will rise under long-term operation, which may cause damage to the motor. Therefore, it is necessary to clean the vents and air inlet devices of the motor in time to avoid blockage to alleviate the problem of excessive temperature.

5.Voltage selection: The voltage value of the stepper motor is not the driving voltage volt value, and the appropriate driving voltage should be selected according to the driver. Usually, only motors with a nominal 12V use a 12V external voltage.

6.Load matching: For loads with large rotational inertia, motors with large frame numbers should be selected. At higher speeds or large inertia loads, gradual frequency increase and speed increase should be adopted to reduce noise and improve positioning accuracy.

7.Maintenance and care: Regularly check the motor's fixed parts, output shaft, encoder connection cable and power connector to ensure that the connection is firm. Clean the dust and oil on the motor in time to ensure that the motor is in normal condition. 8. Cable protection: Ensure that the cable is not affected by external bending forces or its own weight, and avoid immersion in oil or water. In the case of movement, the cable should be firmly fixed to a stationary part to reduce bending stress.

Source:https://blogg.alltforforaldrar.se/amyda/2024/12/19/structural-characteristics-and-applications-of-bipolar-stepper-motors/

Posted

Dec 19 2024, 12:32 AM

by

Amber16