Getting Started with Laser Engraving

If you've never used a laser engraver before, you might be surprised at what can happen when you finally get into the workshop and start your own machining process. Laser engraving is a versatile application - it can be used to mark medical equipment or aftermarket auto parts that can withstand the harshest conditions, or to commemorate a birthday or special event by marking the date on a souvenir.

Learn about our laser engravers

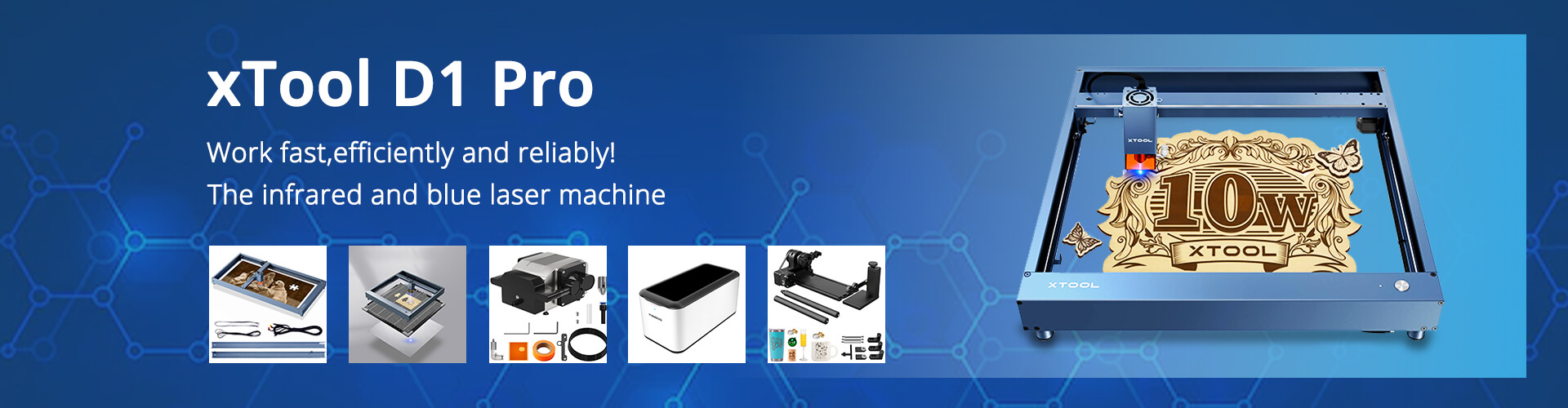

One of the coolest applications for laser engravers we've seen is working with photorealistic photos and images. Our galvo laser systems are so precise that in addition to engraving words and phrases, you can actually engrave photorealistic images into stainless steel. You have to be comfortable with grayscale, but when you get your images set up correctly, this incredible process produces great results. The engraving machine brands we are currently working with are, Atomstack, LaserPecker, xTool, Scunpfun and Ortur, they are all well-known brands of laser engraving machines, with very good and excellent machines, and provide 12-month warranty service

Based on our own trial and error process, we have come up with the ideal step-by-step process for preparing your chosen laser engraving image. With so many different types of laser engravers available, and so many software options for preparing images, it's hard to generalize about a one-size-fits-all approach, but we've done our best to make this guide accessible to everyone. Whether you're an experienced designer working with Corel DRAW or the free online tool GIMP, follow these steps to prepare your images for sculpting.

Learn About Our Laser Engraving Services

Step 1 - Start with a Figh-Quality Image

When choosing an image for laser engraving, it is important to start with a high-resolution, high-quality image. Stamp pictures scanned from old photo albums will not be able to maintain their sharpness through the transformations that need to be done before the image is ready for engraving, and you will not be able to "bloat" or "zoom in" like the picture from a CSI TV show. Make sure Take high-resolution photos with a good camera for best results. Import into the LightBurn software used by the xTool D1 Pro, and you can start preparing your footage for printing.

Step 2 - Cut to Perfection

The advantage of starting with a high-quality photo is that you can effectively crop it and make it look bad. Cut out the parts of the image that you don't want, and resize the rest to the size you want it to appear on the stainless steel or other material you're using.

Step 3 - Remove the Background

This step is important and may require using the clipping tool in your imag e processing software or some handy Photoshop skills. If you don't remove the background, your image may get lost in the background during the engraving process. By making the background of the image pure white and the laser machine engraving only the object in focus, you can avoid obscuring the object with irrelevant background details you don't want.

Step 4 - Convert the Image to Grayscale

Laser engraving naturally produces grayscale images by cutting different lines at different depths for different number of passes. Generating an image in grayscale gives you a good idea of what it will look like when sculpted onto the material of your choice - your image is almost ready! Looking at the grayscale image should help you with the next steps, you'll have to make some slight edits to the image for best results.

Step 5 - Edit Your Photo However You Choose

Now that we're working on something similar to what a laser engraver will produce, we can start making any version that's important to achieve the desired result. Editing photos is a highly subjective process, but we'll offer some advice. These can be applied to photos of people, places or objects.

You want to try to maximize contrast in key areas of your photo. This usually means making whites whiter and dark areas darker.

Areas that appear white in real life, such as eyes or nails, should be highlighted in the image by reducing any shadows that appear there. Set the black to 3-6% to help these areas stand out better.

Remove shadows from any faces in the image, as the dark contrasts too strongly with hair, which is usually darker. Set black to 10-15% for best results.

For dark tresses, darken them. For lighter tresses, you can make them lighter.

Step 6 - Sharpen Your Image

Sharpening just makes lines look thicker, and it's a simple tool that exists in almost every photo editing program. For photos of people, sharpen areas like eyelashes, lips, hair around the face, and any other areas you want to emphasize in the final sculpted image. If you photographed objects or buildings, focus on the most important lines that add texture to the image and give it a three-dimensional feel.

Step 7 - Convert and Export

Your image should now look the way you want it to be sculpted on stainless steel, plywood, or other materials. The next step is to convert this image to a bitmap of the appropriate resolution and transfer it to laser CAD software for engraving. When exporting as a bitmap, the recommended resolution is approximately 200 pixels per centimeter. This ensures that your images are displayed in high resolution on the material of your choice.

Step 8 - Press the Red Button

The last and most fun step is always setting the options on the laser cutter and finally pressing the Ortur Laser Master 3's "Start" button after all the hard work is done. Engraving differs from laser etching in that it makes deeper cuts in the material, and it's usually better to program the laser to make multiple passes over the material, rather than trying to blast a chunk of steel or wood in a single pass. Our galvo lasers use an oscillating mirror system to cut at extremely high speeds, so your project will be complete in minutes.

Or if you just engrave the patterns you need, then I suggest using LaserPecker 2 for marking, which is very compact and portable, and meets your daily marking needs.

In Conclusion

Just follow these simple steps and you'll be amazed how high-quality images you can reproduce on a piece of stainless steel, birch, or laminate. You also don't have to be a graphical wizard -- in fact, it doesn't matter what program you use, as long as it performs the basic functions we've outlined above. Whatever you choose, the most important thing to remember is to start with a clear, high-resolution image. A great picture is a great starting point for creating great creations with our laser engraver.

Posted

Oct 28 2022, 07:19 AM

by

Miao0827